Plastic Mouldings

About

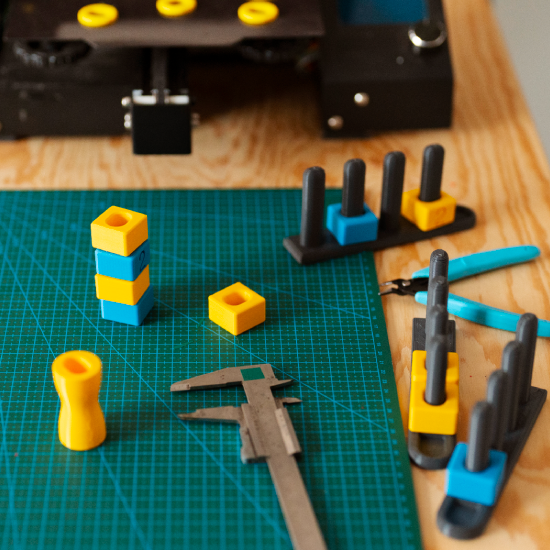

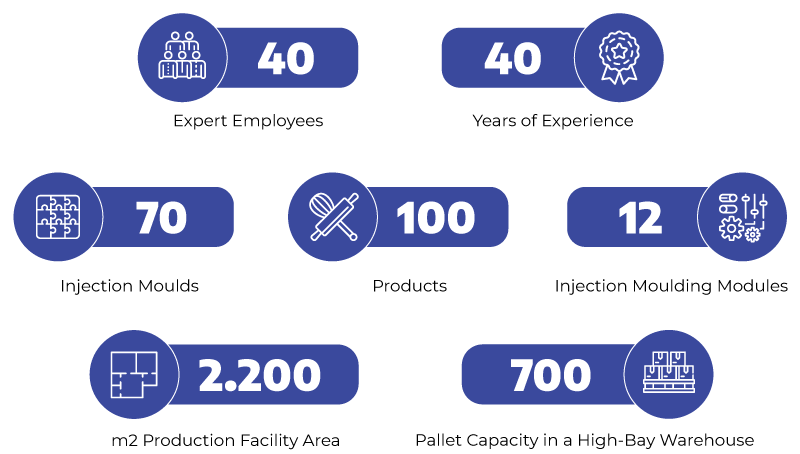

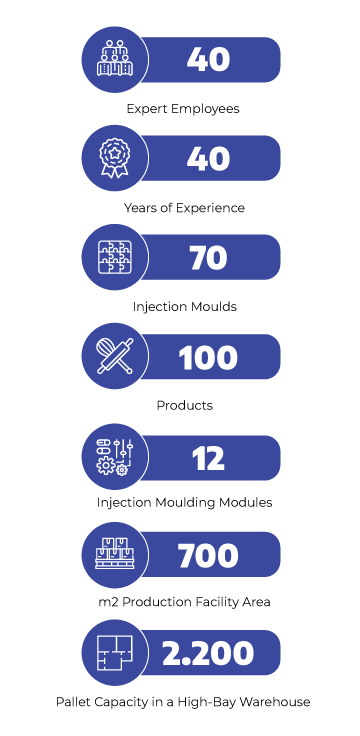

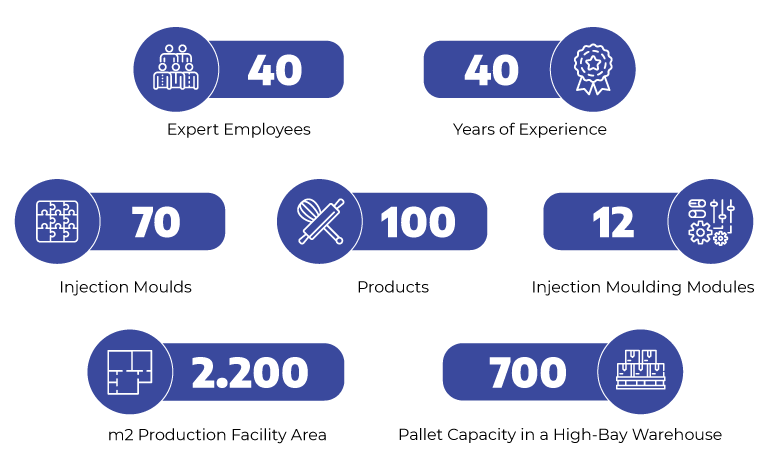

For over 40 years, we have used injection moulding techniques to produce a range of plastic products that meet our clients’ specifications and product design requirements.

Thanks to our expert staff and modern technology park with high-quality equipment, FORMSON guides customers from start to finish. We have worked with clients across a range of industries, including: home appliances, construction, cosmetics, advertising, automotive, filtration, electronics and interior design companies.

FORMSON’s knowledge, practical experience and product offering is extremely broad. Our supportive and friendly team is able to assist customers throughout the production journey – regardless of order complexity